Table of Contents

- Introduction: Unpacking the True Cost of Hat Yarn

- 1.1 Beyond Sticker Price: Why a “Right” Price Doesn’t Exist in a Vacuum

- 1.2 The Global Market Context: Demand, Sustainability, and Regional Dynamics

- Core Factors Determining Hat Yarn Price

- 2.1 The Foundation: Raw Material & Fiber Composition

- 2.2 Spinning Technology and Yarn Construction

- 2.3 Value-Additions: Dyeing, Finishing, and Certification

- 2.4 The Economy of Scale: Order Volume and Market Volatility

- Price Benchmarks by Fiber Type and Application

- 3.1 A Buyer’s Price Framework: Understanding Value Tiers

- 3.2 Comparative Price-Performance Analysis Tables

- 3.3 Total Landed Cost: The Critical Metric for Industrial Buyers

- Strategic Procurement and Case Study: Partnering for Value

- 4.1 The Rise of Technical Partners: From Supplier to Solutions Provider

- 4.2 Case Study: How Glyarn’s Partnership Model Optimizes Cost and Value

- 4.3 A Procurement Framework: Critical Questions for Your Yarn Supplier

- Future Outlook and Conclusion: Smart Spending as a Competitive Advantage

1. Introduction: Unpacking the True Cost of Hat Yarn

What Is the Price Range for Hat Yarn?For procurement managers across apparel, accessories, and home textiles, the question “What is the price range for hat yarn?” is deceptively simple. The immediate number on an invoice—whether $3 or $30 per kilogram—reveals very little on its own. The price is merely an endpoint, a figure shaped by a complex interplay of material science, manufacturing efficiency, global logistics, and consumer trends. In today’s market, where brands are pressured to deliver both sustainability and performance, understanding this complexity is no longer an option; it’s a fundamental strategic imperative. This guide moves beyond simplistic price lists to provide a comprehensive framework for evaluating hat yarn, empowering you to make decisions that balance cost, quality, and long-term brand value.

1.1 Beyond Sticker Price: Why a “Right” Price Doesn’t Exist in a Vacuum

A “low” price can be disastrous if it leads to inconsistent dye lots, excessive pilling in finished beanies, or supply chain delays. Conversely, a “high” price is justifiable if it unlocks superior softness, certified sustainable content, or reliable just-in-time delivery that streamlines your own production. The true measure of cost is not the price per kilogram, but the cost-per-quality-unit-delivered. This encompasses everything from raw material reliability to the yarn’s performance on your knitting machines.

1.2 The Global Market Context

The global headwear market is experiencing significant growth, driven by fashion trends, sun protection awareness, and rising disposable income in emerging markets . For instance, the cap and hat market in regions like Zambia has shown explosive growth, highlighting the global nature of demand . Simultaneously, the broader textile industry is in a “quality upgrade + sustainable development” critical period, with demand for customized, eco-friendly yarns surging . This dual pressure—volume and value—directly impacts yarn pricing and availability.

2. Core Factors Determining Hat Yarn Price

The final price of hat yarn is a sum of its parts. Each stage adds cost and value.

2.1 The Foundation: Raw Material & Fiber Composition

This is the single most significant cost driver, typically accounting for 60-80% of the yarn’s base price.

- Commodity Synthetics (Polyester, Acrylic): Offer the lowest entry point. Basic polyester yarns, widely used for structured caps and affordable beanies, are price-sensitive to petrochemical (PTA/MEG) markets . A basic polyester “hat yarn” can be found at lower price points for bulk orders .

- Natural Fibers (Cotton, Wool): Carry inherent agricultural and processing costs. Premium, long-staple varieties like Egyptian cotton or superfine Merino wool command substantial premiums. As market reports indicate, cotton remains a dominant material in headwear, influencing overall price structures .

- Specialty & Engineered Fibers: This includes recycled materials (rPET, recycled cotton), performance fibers (moisture-wicking, UV-protective), and luxury blends (wool-cashmere, bamboo-cotton). These carry “green” or “technical” premiums. For example, a vendor may offer yarn with specific attributes like high strength or low shrinkage for specialized uses .

2.2 Spinning Technology and Yarn Construction

How the fiber is spun into yarn critically affects both performance and cost.

- Open-End (OE) Spun: A faster, more economical process. OE-spun yarns are bulkier and softer but generally less strong and even. Ideal for bulky knit beanies where a rustic feel is acceptable.

- Ring-Spun: The traditional method producing stronger, smoother, more consistent yarns. Essential for finer-gauge hats, flat-knit styles, or applications requiring high pilling resistance. The process is slower and more costly.

- Yarn Structure: Simple single-ply yarns are cheapest. Plied yarns (2-ply, 3-ply) are more stable and durable, adding cost. Fancy constructions like slubs, bouclés, or corespun yarns (e.g., cotton sheath over a stretch filament) involve complex machinery and add significant value and cost.

2.3 Value-Additions: Dyeing, Finishing, and Certification

- Dyeing: Stock-dyed (yarn-dyed) yarns, where color is integrated during spinning, are more colorfast but require large minimums. Package-dyed yarns offer flexibility for smaller lots but at a higher unit cost. Solution-dyed (dope-dyed) synthetics, where pigment is added to the polymer melt, offer supreme colorfastness but are only viable for massive runs.

- Finishes: Functional finishes like anti-pilling, softness enhancement, or water repellency add processing steps and cost.

- Certifications: Credentials like OEKO-TEX Standard 100 (for harmful substances), GRS (Global Recycled Standard), or organic certifications are no longer just marketing tools. They are often mandated by major brands and represent verified supply chain integrity, adding a justifiable premium. Leading suppliers now offer certified custom yarns as a core service .

2.4 The Economy of Scale and Market Volatility

Price is intrinsically linked to order volume. A 100-ton order will have a vastly different per-unit cost than a 500kg order. Furthermore, yarn prices are not static. They are subject to volatility from raw material indexes (Cotton A Index, oil prices), energy costs, and geopolitical factors affecting trade. Professional suppliers mitigate this through long-term contracts and transparent pricing models.

3. Price Benchmarks by Fiber Type and Application

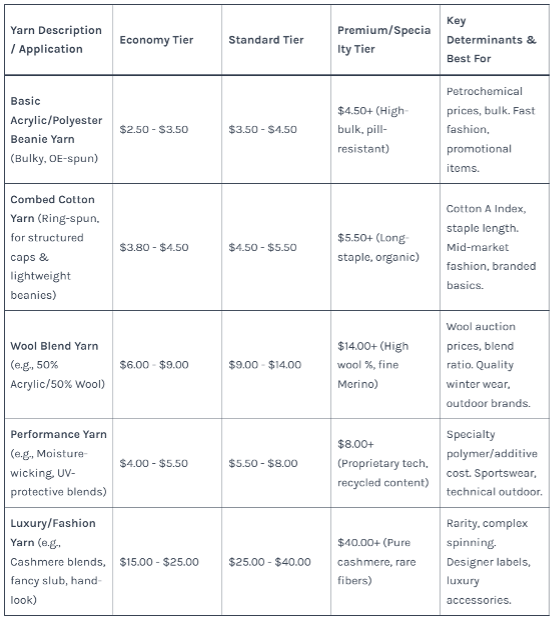

Table 1: Hat Yarn Price-Performance Framework (Indicative Ranges)

Note: Prices are indicative FOB Asia/Europe per kilogram for container-sized orders and fluctuate with raw material markets. “Tier” refers to quality and service level.

3.3 Total Landed Cost: The Critical Metric

The EXW (Ex-Works) price is just the beginning. Smart buyers calculate Total Landed Cost (TLC):

TLC/kg = EXW Price + Freight + Insurance + Import Duty + Tariffs + Inland Logistics + Financing Costs

A yarn that is $0.50/kg cheaper EXW but ships via slower, less reliable logistics can end up costing more in production delays and inventory holding costs than a slightly more expensive but agilely supplied alternative.

4. Strategic Procurement and Case Study: Partnering for Value

4.1 The Rise of Technical Partners

The market is moving beyond transactional suppliers to solution-oriented partners. As industry analysis notes, the winners are companies that offer not just yarn, but “technical strength (spinning process and raw material control), service quality (customization and delivery efficiency), market reputation (customer repurchase and industry evaluation), and innovation capability (environmental protection and trend linkage)” . Brands like Glyarn exemplify this shift.

4.2 Case Study: How Glyarn’s Partnership Model Optimizes Cost and Value

Consider a mid-sized European hat manufacturer launching a new line of sustainable, premium beanies. Their challenges were: 1) Sourcing a consistent, soft blend with recycled content, 2) Achieving vibrant, colorfast hues for a small-batch collection, and 3) Managing cost to hit a specific retail price point.

A traditional supplier might offer a stock recycled acrylic yarn at a set price. Glyarn, acting as a partner, engaged differently:

- Value Engineering: Instead of a standard 100% recycled acrylic, Glyarn’s technicians proposed a custom 70/30 recycled cotton-recycled polyester blend. This utilized more cost-effective rPET for structure and durability, while the recycled cotton provided the desired softness and natural feel, optimizing the cost/performance ratio.

- Supply Chain Innovation: Leveraging their vertical integration and digital color management, Glyarn was able to offer small-batch package dyeing with a 10-day turnaround for the manufacturer’s eight seasonal colors. This eliminated the need for large minimums and deadstock inventory, reducing the client’s working capital burden.

- Total Cost Clarity: Glyarn provided a comprehensive TLC quote, including bundled logistics to the client’s factory in Eastern Europe. While the EXW price per kg was higher than a generic acrylic, the final cost per finished beanie was 12% lower due to reduced waste, faster production speeds (thanks to yarn consistency), and zero shipping delays.

This partnership transformed yarn from a commodity into a strategic enabler, allowing the manufacturer to launch a higher-margin, on-trend product line.

4.3 A Procurement Framework: Critical Questions for Your Yarn Supplier

- Can you provide a cost-breakdown for this quote (material, spin, dye, finish)?

- What is your policy on raw material price adjustments, and how do you hedge volatility?

- Can you share third-party test reports for pilling, shrinkage, and colorfastness relevant to my end-use?

- What is your minimum order quantity (MOQ) per color, and what are the lead times for sampling vs. bulk production?

- Do you hold certifications (OEKO-TEX, GRS, BCI) and can you ensure traceability in the blend?

- What is your on-time-in-full (OTIF) delivery performance over the last 12 months?

5. Future Outlook and Conclusion: Smart Spending as a Competitive Advantage

The future of hat yarn is defined by circularity, traceability, and customization. The price premium for recycled and bio-based fibers will normalize as scale increases. Digital platforms will enable even more dynamic, small-lot sourcing. In this environment, the most significant cost is not the price of yarn, but the cost of a poor partner—one that causes quality failures, misses deadlines, or lacks the innovation to keep your brand relevant.

Therefore, the answer to “What Is the Price Range for Hat Yarn?” is not a number, but a strategy. It is about building relationships with agile, technically proficient partners like Glyarn, who can co-engineer solutions that deliver value far beyond the invoice. By shifting focus from price-per-kilo to total value-per-partnership, procurement managers can transform their yarn sourcing from a backend cost center into a frontline driver of product excellence, brand integrity, and sustainable profitability. The right yarn, at the right true cost, is the very fabric of your competitive edge.